Abstract

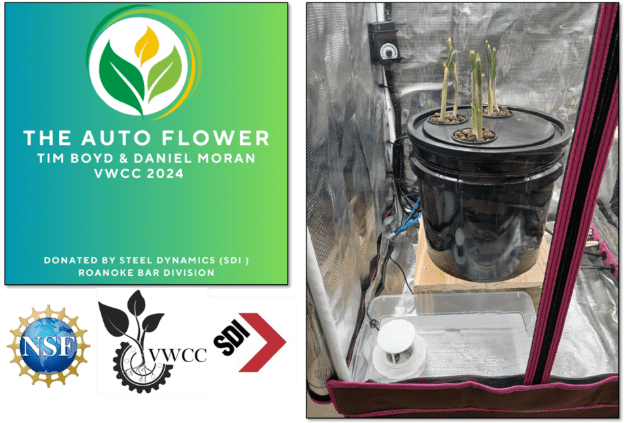

Agriculture is Virginia’s largest private industry, providing nearly $82.3 billion dollars annually. With this in mind, Virginia has increased its investments in agriculture and has prioritized its research into alternative farming techniques. One such focus area is that of Controlled Environment Agriculture (CEA). CEA involves growing crops in environments that are optimized to produce substantially higher crop yields while more efficiently using resources like light, water, land, and nutrients. CEA and techniques related to it require a more diverse set of skills than conventional farming due to the integration of technology necessary to control, automate, and measure crops in a manner that produces the efficiency gains necessary. Virginia Western Community College, located in Roanoke, Virginia, was awarded a 3-year National Science Foundation (NSF) Advanced Technological Education (ATE) grant in June of 2024 to implement a program for combining agriculture and mechatronics into an associate degree for agriculture technicians. This program acknowledges the overlap in competencies that are necessary to meet the needs of future farms. In support of this effort, the Mechatronics and Agriculture Programs are actively cross-pollinating the skill sets in the respective lab exercises. A capstone project that exemplifies this effort and represents equal parts mechatronics and agriculture was undertaken in the Fall 2024 semester by student interns at industry partner Steel Dynamics, LLC (SDI). The sponsored project far exceeded the learning objectives of the capstone class, excelling in teamwork, critical thinking, research literacy, and communication skills in addition to the time management, project planning, and budgeting required by their employer.

Keywords: Controlled Environment Agriculture (CEA), agriculture, agriculture technicians, hydroponics, capstone project, Virginia.

© 2025 under the terms of the J ATE Open Access Publishing Agreement

Introduction

Virginia Western Community College (VWCC) maintains a strong alignment with Career and Technical Education (CTE) by offering programs specifically designed to prepare students for technical careers and workforce advancement. These programs emphasize hands-on learning and the development of industry-relevant skills through multiple educational pathways. Recognizing that industry partners are best positioned to define the skill sets required for employment, VWCC actively encourages employer engagement through campus events, facility tours, and collaborative projects. This paper highlights the value of industry-sponsored capstone experiences by presenting a case study of a project supported by Steel Dynamics, Inc. The featured student team developed an automated hydroponics system that not only outperformed peer projects but also significantly surpassed course expectations and ABET-defined learning outcomes.

Background

Virginia Western Community College’s (VWCC) Associate of Applied Science (A.A.S.) in Mechatronics is one of several CTE-focused programs within the School of STEM. Career and Technical Education (CTE) plays a vital role in supporting regional workforce development and meeting the needs of local employers. Effective CTE programs strengthen the connection between secondary and postsecondary education and help bridge the gap between classroom instruction and real-world application. At VWCC, A.A.S. programs are encouraged to maintain a Curriculum Advisory Committee (CAC), composed of voluntary industry members who provide valuable insights into emerging trends and workforce demands. These insights help inform and shape the development of programs.

CTE programs have long promoted apprenticeships and internships as essential components of student learning. Even short-term exposure to real-world work environments has been shown to enhance classroom performance. Employer engagement exists on a spectrum—from advisory roles on the CAC to offering short-term projects to fully sponsoring students throughout their academic journey. Steel Dynamics, Inc. (SDI) represents the most engaged end of this spectrum, having developed an in-house program that allows employees to compete for a full two-year sponsorship. Since its inception, students participating in this program have consistently ranked among the top performers in the Mechatronics program.

In the fall of 2025, SDI-sponsored students began exploring potential capstone projects. Concurrently, VWCC was in the first year of implementing a National Science Foundation (NSF) Advanced Technological Education (ATE) Grant initiative aimed at integrating mechatronics and agricultural skill sets. The grant supported the development of a new associate degree pathway that combined these disciplines. Its objectives included curriculum development, outreach to prospective and current students, and the creation of lab experiences that fostered appreciation for both fields.

The SDI-sponsored students developed a capstone project that aligned with course rubrics, addressed employer-identified skills gaps, and supported the goals of the NSF Ag-Tech initiative. The resulting project significantly exceeded academic expectations and demonstrated the powerful synergy between industry sponsorship and applied learning.

Capstone Projects in Mechatronics

Each fall, Virginia Western Community College offers a core Mechatronics course focused on Computer Integrated Manufacturing in a 16-week format. The course introduces fundamental principles for designing and implementing computer-integrated manufacturing systems, with an emphasis on hands-on, team-based projects. These projects typically involve tasks such as conveyor control, sensing, measurement, and the documentation of programming and wiring.

Students are organized into teams of two and assigned an automation project early in the semester. The project runs in parallel with labs and lectures, which are designed to reinforce key concepts as they become relevant to the project’s development. Students are not given a budget but can request additional hardware if it is identified.

While the specific application of each project may vary, all teams must meet the same core requirements. A standardized grading rubric, provided in Supplemental Materials, is applied uniformly across all groups. This rubric outlines the weighted components of the project, which is divided into four categories: Presentation, Assembly, Programming, and Engagement. Notably, 50% of the project grade is based on teamwork and effective communication.

The course culminates in a final presentation, during which each team delivers a working prototype, complete with documented programs, wiring schematics, and a formal presentation to an audience of faculty, staff, and peers.

Methods

The final automation project for the fall semester is designed to integrate all course content into a functional, hands-on application assembled in a trainer format. The evaluation rubric, provided in Supplemental Materials emphasizes the construction of a programmable logic controller (PLC) trainer based on a topic selected by the students or assigned by me, the instructor.

As this is the first course in a two-course sequence, the learning objectives focus on digital inputs and outputs controlled through effective ladder logic programming. Students are taught proper wiring techniques, sensor selection, and are provided with most of the components necessary to build a working prototype. While project scopes vary, a typical project involves assembling a tabletop trainer that uses relays to control the forward and reverse motion of a conveyor. Sensors positioned along the conveyor detect variations in object height or width, enabling the system to make decisions and manipulate objects accordingly.

Students are assessed based on their submitted reports, presentations, and completed prototypes. The rubric serves as a guideline for determining whether learning outcomes have been achieved. Additionally, project outcomes are mapped to ABET (Accreditation Board for Engineering and Technology) student outcomes to ensure alignment with industry-recognized standards [1]. Although this capstone project concludes a two-year technical degree, ABET criteria provide a valuable framework for defining clear, measurable learning outcomes.

A mapping of the project’s minimum required learning objectives to published ABET outcomes is shown in the table below.

Table 1: Project Outcomes

| Assignment Objective | Aligned ABET Outcome(s) | Explanation |

| Understand the use of digital and analog sensors as inputs to a PLC | 1, 7 | Applies technical knowledge and recognizes the need to adapt to evolving technologies. |

| Demonstrate proper wiring management and labeling | 1, 2 | Involves technical skills and attention to detail in system design. |

| Demonstrate proper selection of inputs to the PLC | 1, 2 | Requires analysis and application of technical knowledge to solve problems. |

| Create a logic program for your process | 1, 2 | Involves problem-solving and applying engineering principles. |

| Program the PLC using proper programming methods (commenting, subroutines, etc.) | 1, 3 | Combines technical skills with clear communication through code documentation. |

| Understand how to program physical outputs of the PLC | 1, 2 | Applies technical knowledge and system-level thinking. |

| Understand the limitations of the PLC outputs (current, voltage, etc.) | 1, 4 | Involves understanding real-world constraints and their impact. |

| Modify the outputs to overcome limitations (i.e., relays, switches, controllers, etc.) | 2, 4 | Demonstrates creative problem-solving within constraints. |

| Demonstrate the working process | 3, 5 | Requires communication and teamwork to showcase results. |

| Present the project to peers | 3, 5 | Focuses on oral communication and collaboration. |

Positionality Statement

As the author of this research, the lead instructor for this course, and the Principal Investigator (PI) on the associated grant, my primary objective is to effectively combine the academic and experiential accomplishments of my students. My role involves designing and facilitating hands-on, interdisciplinary learning experiences that integrate mechatronics and agriculture with the goal of engaging a diverse student population in applied STEM education.

The initiative is conducted in partnership with Dr. Mallory White, Co-Principal Investigator (Co-PI) and faculty member in the Science Department. Dr. White contributes subject-matter expertise in agricultural sciences and curriculum design. Her involvement also extends to the evaluation of student deliverables, including presentations and technical reports. Our collaboration is grounded in a shared commitment to expanding access to STEM education for students from diverse academic and demographic backgrounds.

The student team, composed of Timothy Boyd and Daniel Moran, brings valuable industry experience to the project through their employment at Steel Dynamics Inc. (SDI) Long Bar Division in Roanoke, VA. Both students are in their final semester at Virginia Western Community College, with a strong track record of collaboration on multiple team-based projects over their two-year academic tenure. Their dual roles as students and industry employees provide a unique lens through which they engage with the course material, offering practical insights that enrich the learning environment for their peers.

This research exemplifies a collaborative model that bridges academic instruction, industry engagement, and interdisciplinary integration. By leveraging the distinct strengths of faculty and students, the project fosters a dynamic learning environment that supports the goals of the ATE program: to prepare a highly skilled technical workforce and to promote innovation in STEM education. Acknowledging the varied roles and experiences of all participants is essential to understanding the success of this project and how it might be translated to future classes.

Results and Discussion

The final capstone project resulted in a fully functional, automated hydroponics system designed and assembled by the SDI-sponsored student team. The system incorporated a programmable logic controller (PLC), human-machine interface (HMI), and multiple sensors to monitor and control water flow, nutrient levels, and lighting conditions. The prototype met all core project requirements and demonstrated reliable operation during the final presentation.

Evaluation of the project was based on the rubric outlined in the Supplemental Materials which assessed four key areas: Presentation, Assembly, Programming, and Engagement. The team achieved high marks across all categories, particularly in programming quality and system integration. The capstone project was mapped to ABET Student Outcomes 1, 2, 3, 4, 5, and 7. These outcomes represent the minimum required outcomes for each two-person team. However, the sponsored team exceeded all the minimum required outcomes. Each component of the sponsored project is shown in detail in the following sections and compared and contrasted with the original requirements and other team outcomes.

Background Research

Capstone projects in the Mechatronics program typically emphasize the automation of a task using hardware and software introduced during lectures and therefore require minimal background research. However, the sponsored student team chose to integrate hydroponics into their application, which necessitated a comprehensive literature review. This additional research component aligns with ABET outcomes 1, 4, and 7, as it required students to define technical requirements, consider sustainability and ethical implications, and independently acquire new knowledge.

The project centered on hydroponics, a method of plant cultivation that eliminates soil by using nutrient-rich water. The term “hydroponics” combines “hydro” (water) and the Greek word “ponos” (labor). In these systems, plants are typically supported by inert media such as rock wool and receive nutrients through water-based delivery methods. Common hydroponic techniques include Deep Water Culture (DWC), Drip Systems, Aeroponics, Ebb and Flow, and the Nutrient Film Technique (NFT) [2]. The benefits of hydroponics include efficient space utilization, high yield per square foot, sustainability, and reduced mechanization. However, challenges include the need for precise control of nutrient solutions and the requirement for skilled labor. Operators must possess knowledge in chemistry, plant physiology, agriculture, and applied engineering [3].

To ensure project success, students needed more than a superficial understanding of hydroponic systems. They were required to research the variables that influence plant growth and determine how to measure, program, and automate those variables. Additionally, the team prioritized portability and user-friendliness to support outreach efforts for the Ag-Tech initiative. This design consideration aligns with ABET outcome two, which emphasizes engineering design within environmental and practical constraints and exceeds the assignment rubric.

The team selected the Deep Water Culture (DWC) method, in which plants are suspended above a water reservoir and stabilized using porous air stones. The roots extend into the water, which is continuously oxygenated via an air bubbler. Nutrients are added to maintain optimal conditions. Although DWC systems are popular among home growers due to their simplicity, they are highly sensitive to environmental variables such as humidity, temperature, light, and water chemistry.

Maintaining proper water chemistry is critical. For leafy greens, optimal pH levels range between 5 and 7. The pH scale, which measures hydrogen ion concentration, is logarithmic and ranges from 1 (acidic) to 14 (basic), with 7 being neutral. Tap water typically has a pH near 7. Because plants in hydroponic systems are directly exposed to water, even minor pH fluctuations can lead to crop failure. Electrical conductivity (EC), measured in milliSiemens per centimeter (mS/cm), is another key parameter. EC reflects the nutrient concentration in the water and must be maintained within crop-specific ranges. Nutrients such as potassium, nitrogen, and phosphorus are commonly added as soluble salts, along with secondary and micronutrients as needed. One of the primary challenges of hydroponics is the ongoing need to monitor and adjust water chemistry, as plant uptake and environmental conditions can alter nutrient levels. Over-treatment can also result in wastewater containing harmful levels of nitrates and phosphates [2].

In addition to conducting background research, the students demonstrated a strong understanding of water chemistry and its implications for system performance. This aligns with ABET outcome six, as they were able to collect, analyze, and interpret data to draw meaningful conclusions about system behavior and plant health. Capstone projects normally require very little background research because the emphasis is on the automation of the task using the hardware and software discussed in lectures. The sponsored students wanted to successfully integrate hydroponics into their application, which required a literature review. The additional ABET outcomes that align with this component of the project are outcomes 1, 4, and 7. The background research was necessary to understand the problem requirements. The research informed the students about the sustainability of such a project, and it demonstrates the ability of the students to seek out knowledge independently.

Industrial Automation

Automation in advanced manufacturing has been transformative. While it is difficult to pinpoint the exact origin of Industry 4.0, it is evident that its principles are now embedded in daily industrial operations. Similarly, automation has revolutionized agriculture by enabling data-driven decision-making, precision resource allocation, and optimization of inputs to significantly increase yields. These practices fall under the umbrella of precision agriculture, which emphasizes the efficient use of raw materials. Furthermore, automation and robotic farming techniques are poised to reshape agricultural labor, potentially leading to broader economic impacts that are not yet fully understood [4-6].

Students surveyed previous studies that explored hydroponics control using both industrial-grade and IoT-based microprocessors in conjunction with various sensors[7-11]. For this project, the student team focused on integrating a widely used industrial programmable logic controller (PLC) manufactured by Allen-Bradley, which is commonly adopted by regional industry partners. This PLC serves as a robust, industry-hardened microcontroller capable of coordinating peripheral sensors and actuators within a 24-volt system. Both analog and digital sensors were essential for monitoring the hydroponic variables discussed earlier. Small-scale industrial pumps and flow meters interfaced seamlessly with the PLC to manage the water exchange system, while humidity and temperature were also regulated through the PLC—mirroring control strategies used in manufacturing environments.

The minimum learning outcomes for the assigned project were based on the implementation of an automation system primarily utilizing digital sensors and actuators. Although analog sensing is introduced in the course, it is not covered in depth until later in the semester and, therefore, is not a required component of the project. However, the sponsored team’s research indicated that analog variables such as humidity and temperature were critical to the success of their hydroponics system. As a result, they chose to incorporate multiple analog inputs, which required sensor installation, calibration, and signal conversion. This process aligns with ABET outcome six, which emphasizes the ability to develop and conduct appropriate experimentation, analyze and interpret data, and apply engineering judgment to draw conclusions.

System Construction

After outlining the design constraints of the Deep Water Culture (DWC) hydroponics system, the students proceeded to design the control components necessary to optimize the growing process. At the core of the control system is an Allen-Bradley MicroLogix 1400 Programmable Logic Controller (PLC). This platform is commonly used in the academic controls classroom due to its robustness and ease of programming.

To effectively monitor the hydroponics system, eleven analog sensors were incorporated. Analog sensors used in industrial monitoring applications typically operate on either a 0–10 volt or 4–20 milliamp linear scale. A combination of sensor types was required to capture all the process variables listed in the table below. Additionally, the sensors varied widely in control voltage, ranging from 5 VDC to 120 VAC.

The students identified the minimum system inputs and outputs, also listed below, to be managed through a relay interface. This approach limits the current load on the PLC and accommodates the diverse voltage requirements of the connected sensors.

Table 2: Hydroponics Input and Output Table

| Analog Inputs | Digital Outputs | |

| Reservoir Ph | Reservoir Ph-Up Pump | Peltier Cooler for Water |

| Reservoir Electrical Conductivity | Reservoir Ph Down Pump | Main Tank to Waste Pump |

| Reservoir Temperature | Reservoir Nutrient Pump | Main Tank to Waste Valve |

| Reservoir Water Level | Main Tank Ph Up Pump | Ph UP Reservoir Solenoid |

| Main Tank Ph | Main Tank Ph Down Pump | Ph Down Reservoir Solenoid |

| Main Tank Electrical Conductivity | Main Tank Nutrient Pump | Plant Food Reservoir Solenoid |

| Main Tank Temperature | Main Tank Sub Pump | Ph Up Main Tank Solenoid |

| Main Tank Water Level | Reservoir Sub Pump | Ph Down Main Tank Solenoid |

| Waste Water Level | Lighting | Plant Food Main Tank Solenoid |

| Ambient Temperature | Exhaust Fan | Reservoir to Main Tank Pump |

| Ambient Humidity | Air Pump for Main Tank | Reservoir to Main Tank Valve |

| Reservoir to Main Tank Pump | Peltier Cooler for Water | |

| Reservoir to Main Tank Valve | Main Tank to Waste Pump | |

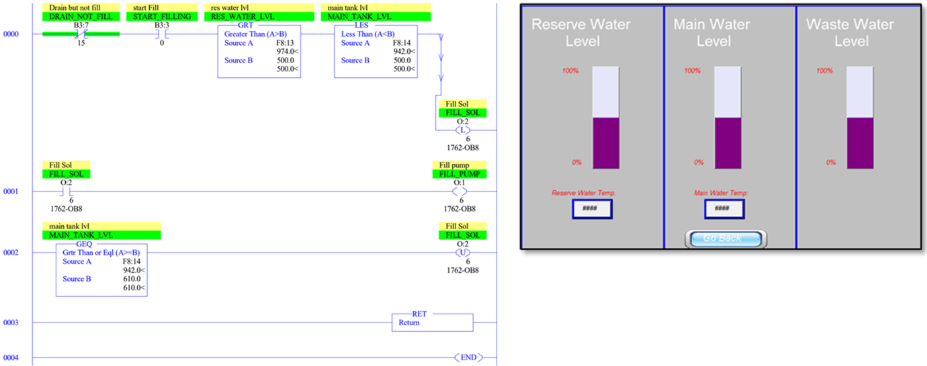

Communication with the PLC was established via Ethernet/IP using MicroLogix 500 software from Rockwell Automation. The Allen-Bradley software is used to program the controller using the ladder logic programming language. To enhance operational flexibility, a Human-Machine Interface (HMI) was implemented for all operator functions. The HMI communicates with the PLC through an Ethernet switch, enabling near real-time responsiveness. Compared to physical switches, the virtual display offers superior graphics, flow diagrams, analog readouts, and the flexibility to make iterative changes without the need for costly hardware modifications.

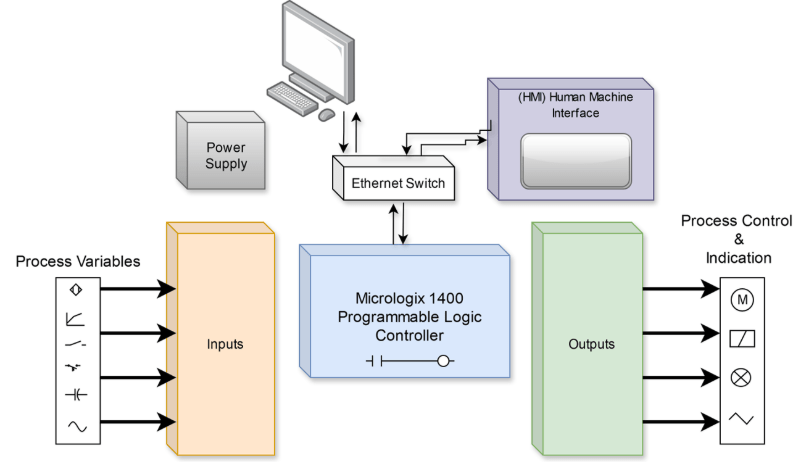

The block diagram created by the team in Fig. 1 represents an overview of how the specified pieces function together. The inputs to the PLC consist of a variety of sensors monitoring the process variables, and the outputs will be used to drive the process and indicators or alarms.

Students in this course are not typically introduced to HMI programming or PLC networking. Most student projects rely on hardwired digital switches and indicator lights. Additionally, off-the-shelf PLCs have a limited number of input/output (I/O) points, and projects are usually scoped to remain within these constraints. However, the sponsored team expanded the project significantly by increasing both the quantity and variety of I/O, developing the HMI interface, and networking the HMI to the PLC via an Ethernet switch. Their initiative to learn and apply these advanced techniques independently demonstrates a level of achievement that clearly exceeds the expectations of ABET outcome seven, which emphasizes the ability to acquire and apply new knowledge using appropriate learning strategies.

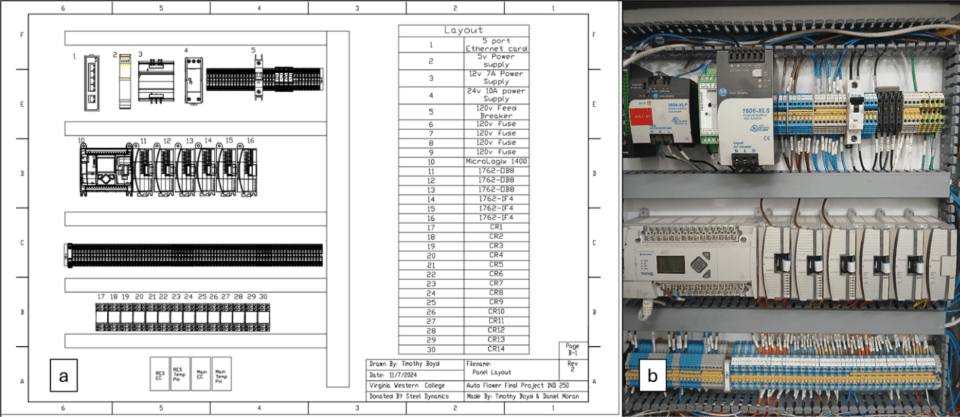

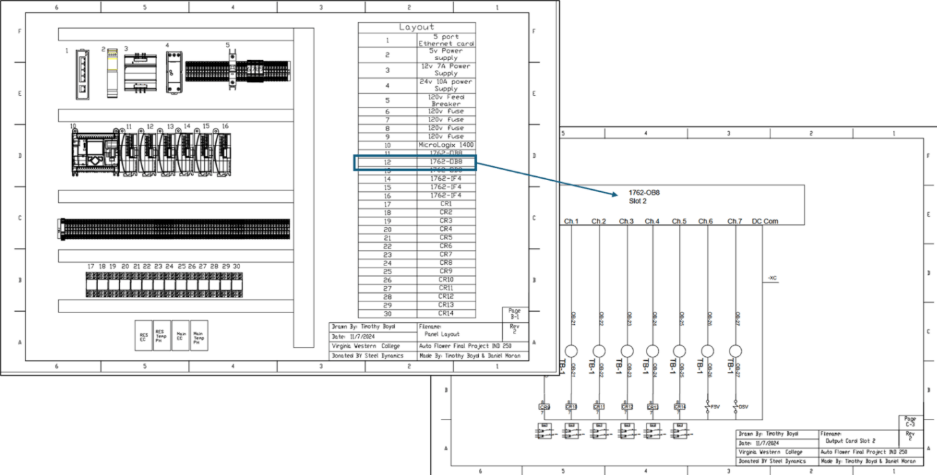

Before assembly, students used AutoCAD Computer Aided Drafting (CAD) software to accurately outline the required physical space for the real-world components and wire channels. The enclosure was then specified and purchased by SDI, Inc. for assembly Fig. 2 illustrates how the drawing was used to facilitate the placement of the components. The entire control panel was custom-built in the lab to match the plan.

In addition, a complete set of schematics was designed, printed, and compiled for future reference. The intent is to enable the unit’s use in future instructional labs; therefore, the full drawing set is stored in the control cabinet alongside the unit. An example of the thoroughness of the documentation is illustrated in Figure 3. Drawing B-1 (left) references the outputs on Slot 2 of the PLC while Drawing C-3 (right) provides a detailed breakdown of each control relay and solenoid, including appropriate electrical symbology.

Adequate documentation is a critical component of the capstone project requirements each year, as it reflects both attention to detail and sound engineering design practices. All students are required to submit an accurate schematic of their assembly, although many complete the schematic after the physical build is finished. For small-scale projects, it is common for students to submit hand-drawn wiring schematics to fulfill the rubric.

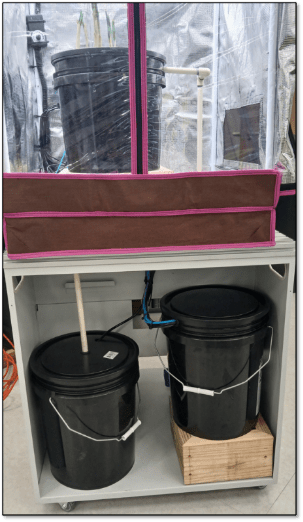

Sensing and Calibration

As shown in Fig. 4, the plants are cultivated inside an enclosure called a grow tent [12], [13]. An enclosure helps prevent pests and, when closed completely, creates a microclimate. The micro-climate can be thought of as a small analogy of a larger space utilized for (CEA). There are many benefits to the enclosed growing environment if it is monitored and controlled. The temperature, light, and humidity within the space can be controlled to maintain the optimum conditions. The grow tent shown will be sealed during the growth phase to allow only the controlled light. The water tanks also limit light exposure because, under ideal temperature and humidity conditions, other unwanted bacteria or plant life will tend to propagate as well. To limit light exposure, it is imperative that the conditions within the tent be monitored accurately via real-time sensing while the tent is closed.

As others have reported, water chemistry in hydroponics must be continuously monitored to ensure plant health and maximize yield [10], [14]. The general consensus is that pH and electrical conductivity (EC), when properly monitored, are the minimum indicators required to maintain healthy water chemistry in a hydroponic system. While the benefits of soil-free farming have been well-documented, one significant disadvantage is the rapid responsiveness of nutrient levels. In soil-based environments, nutrient availability is buffered by the soil, creating a natural hysteresis that mitigates sudden changes. In contrast, hydroponic systems lack this buffer, meaning that rapid fluctuations in nutrient concentrations can immediately impact plant health and yield[15].

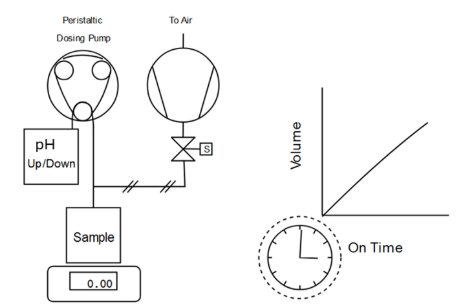

To address this, both pH and EC must be monitored and adjusted gradually and accurately to prevent overcorrection, which can lead to plant stress or death. The first challenge is delivering a known dose of both nutrient solution and pH adjusters to the reservoirs. To accomplish this, students sourced peristaltic pumps to dose the required solutions into the reservoir and main tank. These pumps move a fixed volume of liquid through a sealed system without direct contact with the fluid being transferred. In this application, the liquids included off-the-shelf pH up, pH down, and plant nutrient solutions formulated for hydroponic use. Each of these concentrated solutions required predictable dilution, which varied depending on the water source.

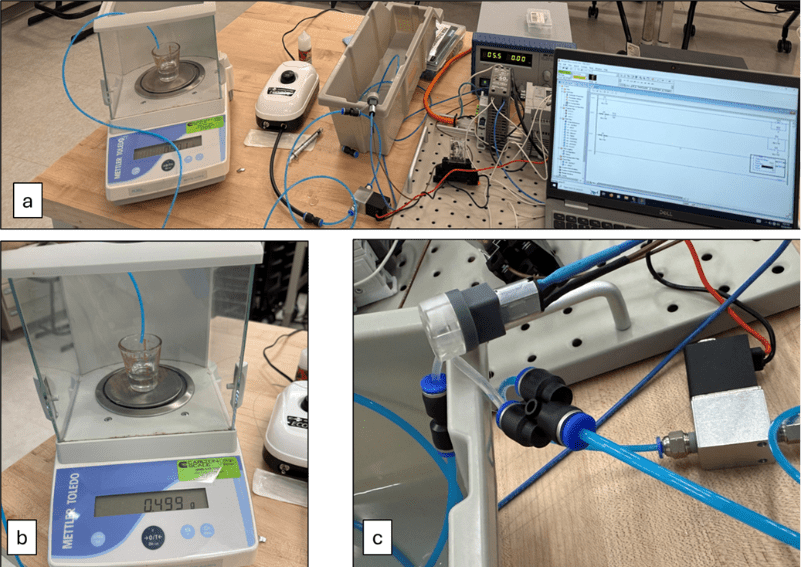

To ensure dosing accuracy, students developed a calibration test bed to determine the relationship between pump run time and output volume. They replicated the setup used in the actual hydroponic system and conducted multiple tests, using a scale to measure the time required to dispense 0.5 grams of solution. The data were recorded, plotted, and analyzed to generate a trendline, which was then used to determine the optimal pump run time for achieving the desired dilution. An illustration of the calibration process is shown in Figure 5.

The actual calibration test bed is shown in Fig. 6. The air pump is incorporated into the feed system to accelerate the mixing process and help deliver the higher viscosity concentrate. To mimic the actual conditions, the same air pump is utilized in the calibration test bed shown.

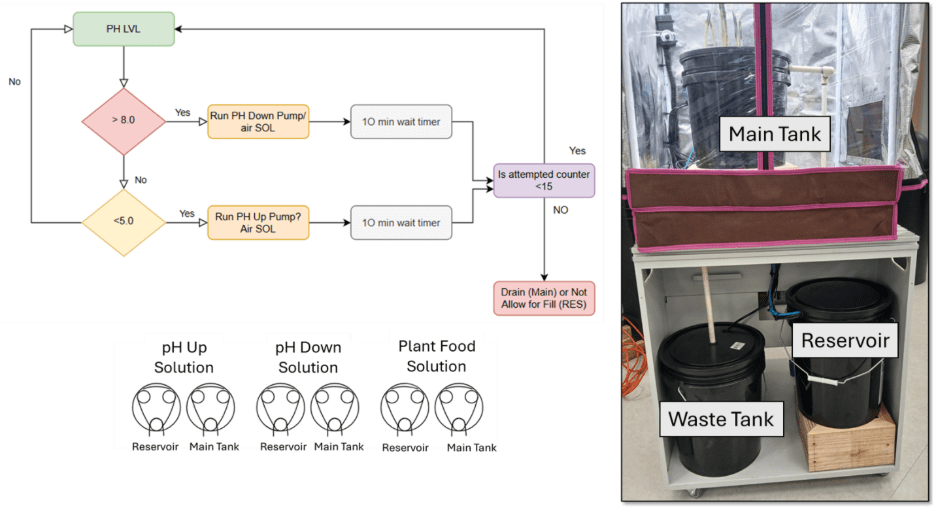

As mentioned previously, the disadvantage to the water-based growing methods is how rapidly the water chemistry can change. Students attempted to mitigate the rapid change in water chemistry using a programming solution to limit the amount and timing of water chemistry changes. First, to ensure the solution was sufficiently mixed, a timer was programmed to wait up to ten minutes before remeasuring the water properties. Once changes are made, it is difficult to remove or remedy an error. An additional fail-safe was added to mitigate sensor malfunction by limiting the number of doses the system would allow for a given dose protocol. The flowchart shown below in Fig. 7 illustrates how students programmed the pH subroutine to avoid overdosing on the plants.

It should be noted that the students recognized that different plants require varying pH and EC levels. For the first growth experiment, green onions were transplanted into the main tank. The ideal pH range for green onions is between 5.5 and 6.8. With only minor exceptions, most plants require a pH no lower than 5.5. The upper pH limit for the types of crops we plan to focus on typically does not exceed 6.8 [16]. The flowchart above, created for the student presentation, indicates a high limit of 8 and a low limit of 5. These specifications can be easily adjusted using the HMI program, and in the future, a separate menu may be incorporated to optimize the nutrient recipe based on plant type.

Every aspect of this portion of the project exceeded both the requirements and expectations. The students performed well above their grade level and did so with remarkable independence. While there were numerous conversations with SDI supervisors and peers, most focused primarily on the selection of hardware components.

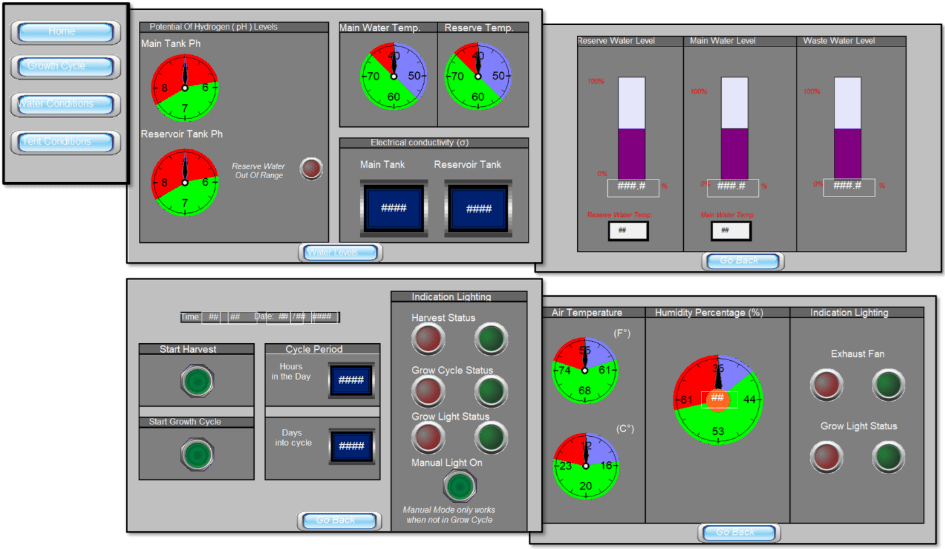

Human Machine Interface

One notable advancement in industrial automation is the widespread use of the HMI for interfacing with control systems. Previous methods of control required physical buttons, switches, and alarms. The disadvantage of these devices is their inflexible footprint. With a large number of inputs and outputs to monitor and change, it makes sense to integrate the most flexible means possible. To optimize control of the hydroponics system, students used a 10-inch Kessler-Ellis Touchscreen Panel that was provided by Steel Dynamics, Inc. (SDI). To program the panel to interface with the PLC, a software called EasyBuilder 8000 was used. The EasyBuilder program allows for the placement of symbology that can internally be assigned to tags within the PLC. For example, a bit within the PLC that goes to a high state during an alarm condition can be assigned to an image in the EasyBuilder software, which reflects the bit status and communicates seamlessly with the operator without accessing the inside of the control panel.

The students aimed to closely monitor the system processes to facilitate easier troubleshooting and control, which required access to a substantial amount of information. One significant advantage of the HMI is its ability to support multiple program flow pages that share the same screen footprint. Fig. 8 illustrates how the students organized the HMI pages to provide a comprehensive view of every aspect of the hydroponic growth system.

To illustrate the consistent and informative method of organization specifically for the user or operator, an example ladder logic subroutine from the student report is shown in Fig. 9. Proper program management not only requires meaningful names and descriptions of variables but also leverages subroutines to help the technician easier identify program areas. The example below is a simple subroutine for managing the transfer of fluid between containers. The HMI reflects the real-time levels of these containers in a meaningful manner using the variables (tags) from the ladder program.

Concepts such as HMI programming, effective ladder logic using subroutines, and thorough commenting and documentation are typically covered in the advanced version of this course. The learning objectives for all student teams emphasized proper commenting practices within a single ladder logic program. Although subroutines and functions were introduced in class, most students were not yet proficient enough to fully integrate these concepts into their final projects. Referencing ABET alignment alone would not capture the full scope of achievement. All students were required to design an engineering project, and most met the expectations. However, the sponsored team significantly exceeded all criteria.

Customized Design and Fabrication

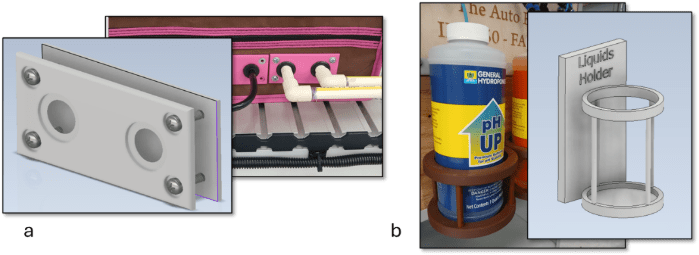

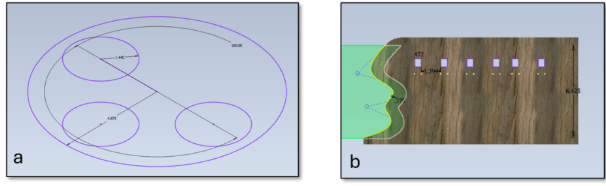

All student teams are encouraged to design and build components for their projects if it enhances functionality; however, this is not a strict requirement. The sponsored team went above and beyond by creating designs in Autodesk Inventor and utilizing 3D printers in our campus Fabrication Lab to produce custom accessories. Several examples of these design components are shown in Fig. 10.

To seal the penetrations through the grow tent, the team designed and printed custom flanges. These flanges were engineered so that the front and back pieces fit together with an inset for a captive nut on the inside, allowing for easy assembly. The plate openings were sized to accommodate standard grommets for pipe fittings. Additional accessories, such as bottle holders, were also designed in CAD and 3D printed.

Not all custom components can be fabricated using 3D printing or additive manufacturing. For example, to create a uniformly spaced plant holder, the reservoir lid was cut using a waterjet cutter. The design was created in CAD and exported as a DXF file for precision cutting (Fig. 11). This ensured a perfect fit for the plant holder. Additionally, the backplate required to mount the peristaltic pumps for nutrient and pH dosing was made from ¼” birch plywood and cut using a laser cutter.

Sponsored students also performed all of their own fabrication work, including basic plumbing, soldering, and assembly skills (drilling, cutting, and wiring). To reiterate, none of these advanced fabrication techniques were required for the project. The sponsored team voluntarily incorporated them and significantly exceeded expectations in every category.

Commissioning

The final project presentation was given to stakeholders from the college in both agriculture and mechatronics disciplines, as well as management representatives of SDI. The hydroponic system, when started, uses a week-long cycle. For the growing cycle, the light will turn on and off for 7-hour periods. When the cycle is complete, the operator can decide to enter harvest mode or continue for another growing cycle. Water chemistry, humidity, and temperature will be sensed continuously during these periods, and alarms will be displayed if anything deviates from the desired setpoint during this time. The recommended cycle was appended for presentation purposes to demonstrate the extent of controls. Green onions were transplanted into the grow tank to resemble an actual growth process. Onions that were transplanted for the presentation continued to grow and were thriving days later as the hydroponics unit continued its programmed cycle.

Due to the advanced nature of the sponsored student project, the corresponding presentation was significantly more comprehensive and detailed than those of other student teams. The complexity of the functional system necessitated an in-depth explanation of its components and operation. As a result, the submitted slide deck was notably extensive, and the programming implementation exhibited a level of sophistication and nuance that exceeded typical expectations for this course level.

Discussion

The work outlined above highlights aspects of an industrial automation capstone project that surpassed the required scope. A comparison between industry-sponsored and non-sponsored capstone projects reveals several key advantages associated with industry involvement in Career and Technical Education (CTE) programs. Students participating in the industry-sponsored project demonstrated a marked improvement in their ability to locate, evaluate, and apply scholarly and technical resources. This was evident in their more frequent and effective use of sources, including peer-reviewed literature. Sponsored students also benefited from referencing workplace techniques and protocols, particularly for standards such as wiring and assembly. The presence of an industry partner appeared to elevate the importance of problem-solving, motivating students to exceed even the maximum project requirements. Table 3 below illustrates compliance with the initial learning objectives plus any additional outcomes that exceed the requirements.

Table 3: Sponsored Project ABET Aligned Outcomes

| Initial Learning Outcomes for Capstone Project | |||

| Course Learning Outcome | Aligned ABET Outcome(s) | Met/Exceeded/Not Evident | Supporting Evidence |

| Understand the use of digital and analog sensors as inputs to a PLC | 1, 7 | Exceeded | -Sensing and Calibration: Use of pH and EC sensors with real-time monitoring. -System Construction: Eleven analog sensors documented. – Block Diagram (Fig. 1): Inputs feeding into PLC described. – HMI Section: Display of analog values on the touchscreen panel. |

| Demonstrate proper wiring management and labeling | 1, 2 | Exceeded | -System Construction: Control cabinet assembly. – Wiring schematics created and documented (Fig. 3). – Discussion Section: Standards-based wiring cited by industry reference. |

| Demonstrate proper selection of inputs to the PLC | 1, 2 | Exceeded | -Sensing and Calibration: Choice of pH and EC sensors aligned with needs. – System Construction: Sensor voltage levels documented. |

| Create a logic program for your process | 1, 2 | Exceeded | – Flowchart logic programming is shown (Fig. 7). – Sensing and Calibration: Timer delays and fail-safes implemented. – Commissioning: Grow cycle automation with alarm states. |

| Program the PLC using proper programming methods (commenting, subroutines, etc.) | 1, 3 | Exceeded | – HMI Section: Use of tags and alarms (Fig. 8). – Ladder Logic subroutine for water transfer is shown (Fig. 9). – Mention of variable naming and use of subroutines. |

| Understand how to program the physical outputs of the PLC | 1, 2 | Exceeded | -System Construction: Actuation of pumps, fans, and solenoids. – HMI programming enabled control of outputs. – Calibration testbed involved physical PLC outputs. – Grow tent control: lighting and fans tied to PLC. |

| Understand the limitations of the PLC outputs (current, voltage, etc.) | 1, 4 | Exceeded | -System Construction: Sensors operated on multiple voltages. – Relay system used to manage the load on PLC outputs. |

| Modify the outputs to overcome limitations (i.e., relays, switches, controllers, etc.) | 2, 4 | Exceeded | -Use of solenoids and relays to drive high-power outputs (System Design). – Calibration involved controlled dosing via air-assisted solenoid setup. |

| Demonstrate the working process | 3, 5 | Exceeded | -Commissioning: Functional grow cycle executed. – Sensing and Calibration: Physical system tested and refined. – Fabrication: Custom hardware implemented and tested in the system. |

| Present the project to peers | 3, 5 | Exceeded | -Commissioning: Final project demo to VWCC and SDI stakeholders. – Presentation listed as capstone requirement (Supplemental Materials). |

| Additional Outcomes Included for Sponsored Team | |||

| Identify credible and relevant sources of information using academic databases, journals, and other scholarly resources. | 7 | Met | -Background Research: Discussion of nutrient sensitivity informed sensor needs. -Sensing and Calibration: Research on pH needs for specific plants. |

| Develop and implement a calibration procedure for a sensor, ensuring experimental repeatability and reliability.” | 6 | Met | -Sensing and Calibration: Experiment design to determine dosage requirements for change in pH |

| Design and implement a reliable Ethernet-based communication system between multiple devices, ensuring proper addressing, data integrity, and scalability.” | 1,2 | Met | System Construction: Ethernet communication with multiple devices via TCP/IP Block Diagram (Fig. 1). |

| Analyze and document the workflow of a technical process, identifying key steps, decision points, and dependencies | 2,3 | Met | -System Construction: Control panel size determined from CAD drawing. -Documentation of subcomponents for the future. -HMI Section: Logic used to control the dosing system. -Block Diagram (Fig. 1): Inputs feeding into PLC described. |

| Collaborate with team members and supervisors to align project goals with available resources, clearly articulating budget-related risks and recommendations | 2,3 | Exceeded | -System Construction: Control panel requirements -Sensing and Calibration: Peristaltic pumps -HMI: Choice of HMI based on sponsored budget -System Construction: I/O defined by the sponsor based on constraints -System Construction: pH and EC sensors provided by the sponsor based on budget -Sensing and Calibration: Grow tent, lights, heater, and fan chosen with regard to sponsor budget. |

These findings align with educational research suggesting that authentic, real-world contexts significantly enhance students’ critical thinking skills while also improving a range of soft skills [17-20]. ABET (formerly the Accreditation Board for Engineering and Technology) mandates a capstone project as part of an engineering technology baccalaureate program, citing its role in bridging academic and professional practice[1]. Accredited programs must provide an appropriate culminating experience based on knowledge and skills acquired in earlier coursework. Two-year technical programs are well-positioned to offer similar experiences, often maintaining stronger pipelines to employers.

Research on industry-sponsored projects that align closely with company objectives is fairly widespread, and the outcomes are generally positive. Often, these projects result in deliverables for the sponsoring company and, in some cases, lead to employment opportunities for students. However, common challenges include misaligned expectations and overly ambitious project scopes [21]. In our case, continued oversight of the budget and timeline by both faculty and industry mentors helped mitigate these issues. Regular interactions with industry mentors fostered a stronger sense of responsibility and time management, echoing findings from similar studies on work-based learning. In contrast, the non-sponsored project, while still educationally valuable, lacked the external pressure and real-world constraints that often drive innovation and critical thinking. Students were not encouraged to explore broader applications or pursue more complex, relevant solutions.

Finally, while much research has explored the role of industry sponsorship in bridging the gap between education and employment, this project was unique in its focus on agriculture rather than traditional industrial sectors like steel manufacturing. The sponsoring company recognized that the learning objectives were highly relevant to their operations, even though the application differed from their core business. The entire project was built for agricultural use, but its platform was intentionally designed to address skills gaps identified by the employer.

Limitations

While this project highlighted a significant gap in skill level between the sponsored team and the five unsponsored teams, it is important to note that this may have been a unique circumstance. As the instructor, I selected the members of the unsponsored teams, which may have resulted in pairings that lacked effective collaboration. In contrast, the sponsored students had known each other throughout their academic careers and were well aware of each other’s strengths and weaknesses.

Additionally, by the time this project was assigned, the sponsored students had already completed a full year of employment at SDI. They were familiar with their supervisor and had gained real-world experience—an advantage not shared by the rest of the class. Furthermore, due to the nature of the sponsorship agreement, the employer had open access to the student’s grades and instructors. I believe this level of accountability played a key role in maintaining their high work ethic.

Conclusion

In conclusion, capstone projects that incorporate real-world experience are a requirement in many engineering programs and have demonstrated clear benefits for student learning outcomes. Positive results from sponsored projects include improvements in teamwork, critical thinking, research literacy, communication, time management, project planning, and budgeting. These competencies are not only valuable to employers but also address common gaps in traditional technical education.

Innovation is inherently difficult to teach, and students in technical programs are not always motivated to pursue creative or novel solutions. While the factors that inspire students to move beyond rubric-based expectations remain unclear, it is well-documented that many struggle to see the real-world relevance of capstone projects. To address this, technical programs such as the Mechatronics Program at VWCC actively engage industry partners to provide meaningful experiential learning opportunities.

This capstone experience illustrated these benefits by comparing the outcomes of sponsored and unsponsored student teams working under the same constraints. The sponsored team met or exceeded all expected learning outcomes and even achieved several that were not part of the original project requirements. Their motivation and engagement were significantly higher than their peers, resulting in an innovative approach to an agricultural application.

While not all projects yield uniformly positive outcomes, common challenges include tight deadlines, overly ambitious scopes, and inconsistent communication. This particular project—though focused on agriculture rather than steel production—was unique in that its subject matter did not initially align with the employer’s core competencies. However, ongoing communication among all stakeholders ensured that identified skill gaps were addressed in a platform-agnostic manner.

Ultimately, this project exceeded expectations and surpassed the maximum criteria outlined in the grading rubric, delivering a truly innovative solution to a real-world agricultural challenge.

Future Work

Going forward, VWCC will leverage this experience to promote similar partnerships with other regional employers. Our region faces a well-documented shortage of mechatronics professionals, and employers frequently cite deficiencies in work ethic, motivation, punctuality, and communication—skills that are difficult to teach within traditional CTE (Career and Technical Education) programs.

The outcomes of the project described here demonstrate that these soft skills can be effectively developed through real-world experience in an industry setting, particularly when guided by supportive and engaged supervisors. Importantly, the time commitment required from the college is minimal. While our advising staff invests additional time in mapping student pathways in collaboration with employers, this investment is minor compared to the substantial benefits for all parties involved.

Students gain full-time employment and receive pay increases upon graduation, along with guaranteed job placement for at least two years. They also benefit from deeper learning within the same curriculum, influenced by the expectations and involvement of their employer. Employers, in turn, are drawn to this model because it allows them to shape the skill sets of future employees and ensures transparency in what students are being taught.

Additionally, the college benefits from access to emerging technologies that may otherwise be financially out of reach. When sponsors identify and contribute these technologies—along with their time and expertise—it creates a mutually beneficial relationship that enhances the classroom experience.

In summary, the advantages of strong industry-college partnerships far outweigh the additional effort required to maintain them. Moving forward, the goal is to present this model as a template for other employers seeking to cultivate high-quality employees before graduation.

Acknowledgments. This work was supported by the National Science Foundation (NSF) award #2350254 for Advanced Technological Education titled Cross-Pollination Skill sets: Growing Mechatronics and Agricultural Collaborations for Producing Skilled Agricultural Technicians. Additional funding was provided by Steel Dynamics, Inc., Long Products Group, Roanoke Bar Division of Roanoke, VA.

Disclosures The authors declare no conflicts of interest.

Supplemental Material Please see document

[1] ABET, “Engineering Accreditation Commission CRITERIA FOR ACCREDITING ENGINEERING PROGRAMS 2025-2026 Criteria for Accrediting Engineering Programs,” 2024.

[2] R. S. Velazquez-Gonzalez, A. L. García-García, E. Ventura-Zapata, J. D. O. Barceinas-Sánchez, and J. C. Sosa-Savedra, “A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations,” Agriculture, 2022, [Online]. Available: https://api.semanticscholar.org/CorpusID:248470916

[3] S. Khan, A. Purohit, and N. Vadsaria, “Hydroponics: current and future state of the art in farming,” J Plant Nutr, vol. 44, pp. 1515–1538, 2020, [Online]. Available: https://api.semanticscholar.org/CorpusID:233205899

[4] C. Bernier, “Agtech: Automation of Agriculture | Association for Advancing Automation Industry Insights,” 2022. [Online]. Available: https://www.automate.org/industry-insights/agtech-automation-of-agriculture[2/24/2023

[5] L. Ku, “How Automation is Transforming the Farming Industry-Plug and Play Tech Center https://www.plugandplaytechcenter.com/resources/how-automation-transforming-farming-industry/[2/24/2023 2:12:34 PM] How Automation is Transforming the Farming Indusry,” 2022. [Online]. Available: https://www.plugandplaytechcenter.com/resources/how-automation-transforming-farming-industry/[2/24/2023

[6] K. Bazargani and T. Deemyad, “Automation’s Impact on Agriculture: Opportunities, Challenges, and Economic Effects,” Robotics, vol. 13, p. 33, 2024, [Online]. Available: https://api.semanticscholar.org/CorpusID:267765560

[7] C. Joshitha, P. Kanakaraja, K. S. Kumar, P. Akanksha, and G. J. Satish, “An eye on hydroponics: The IoT initiative,” 2021 7th International Conference on Electrical Energy Systems (ICEES), pp. 553–557, 2021, [Online]. Available: https://api.semanticscholar.org/CorpusID:232413955

[8] A. M. S. Ardina et al., “IoT-Based Solar-powered Smart Hydroponics system with Real-Time Monitoring and Control System,” 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), pp. 1–6, 2022, [Online]. Available: https://api.semanticscholar.org/CorpusID:258460388

[9] R. Lakshmanan, M. Djama, S. K. S. Perumal, and R. M. T. Abdulla, “Automated smart hydroponics system using internet of things,” International Journal of Electrical and Computer Engineering (IJECE), 2020, [Online]. Available: https://api.semanticscholar.org/CorpusID:226192620

[10] S. Pawar, S. Tembe, and S. Khan, “Design of an Affordable pH module for IoT Based pH Level Control in Hydroponics Applications,” 2020 International Conference on Convergence to Digital World – Quo Vadis (ICCDW), pp. 1–4, 2020, [Online]. Available: https://api.semanticscholar.org/CorpusID:231683457

[11] S. Sreedhar, K. Raghul, M. Kayalvizhi, and E. Yogeshwaran, “Automated Aqua-Hydroponics System Using Arduino, Plc and IoT,” Bharatiya Vaigyanik evam Audyogik Anusandhan Patrika, 2021, doi: https://doi.org/10.56042/bvaap.v29i2.51915.

[12] K. Nagamine, S. Kamisato, H. Kamehama, and O. Makishi, “Optimization of Growth Conditions in Hydroponics,” The Proceedings of JSME annual Conference on Robotics and Mechatronics (Robomec), 2019, [Online]. Available: https://api.semanticscholar.org/CorpusID:214337927

[13] B. Erfianto, A. Rakhmatsyah, and E. Ariyanto, “Micro-Climate Control for Hydroponics in Greenhouses,” 2020 8th International Conference on Information and Communication Technology (ICoICT), pp. 1–6, 2020, [Online]. Available: https://api.semanticscholar.org/CorpusID:221160315

[14] M. Safira, M. W. Lim, and W. S. Chua, “Design of control system for water quality monitoring system for hydroponics application,” IOP Conf Ser Mater Sci Eng, vol. 1257, 2022, [Online]. Available: https://api.semanticscholar.org/CorpusID:253062872

[15] S. B. Triantino, A. Mulwinda, A. Hangga, A. B. Utomo, N. A. Salim, and A. M. Nisa, “Control System of Nutrient Solution pH Using Fuzzy Logic for Hydroponics System,” 2022 9th International Conference on Information Technology, Computer, and Electrical Engineering (ICITACEE), pp. 71–75, 2022, [Online]. Available: https://api.semanticscholar.org/CorpusID:253124457

[16] H. Singh, G. Assistant, and V. Dunn Bruce, “Oklahoma Cooperative Extension Service,” 2016. [Online]. Available: http://osufacts.okstate.edu

[17] A. B. Ali, D. I. Rosli, I. Sujadi, B. Usodo, and F. A. Perdana, “Mastering the soft skills in the implementation of work based learning among community college students,” in Journal of Physics: Conference Series, Institute of Physics Publishing, Feb. 2017. doi: 10.1088/1742-6596/795/1/012004.

[18] C.-S. Wan, Y. Jen-te, C. Shu-yun, and C. and Su, “A longitudinal study on internship effectiveness in vocational higher education,” Educ Rev (Birm), vol. 65, no. 1, pp. 36–55, Feb. 2013, doi: 10.1080/00131911.2011.634969.

[19] C. Dortch, “CRS Report for Congress Carl D. Perkins Career and Technical Education Act of 2006: Background and Performance Cassandria Dortch Analyst in Education Policy,” 2012. [Online]. Available: www.crs.gov

[20] R. J. Coleman and J. W. Shelnutt, “Fostering university/industry partnerships through sponsored undergraduate design,” in Proceedings Frontiers in Education 1995 25th Annual Conference. Engineering Education for the 21st Century, IEEE, pp. 2a1.8-2a111. doi: 10.1109/FIE.1995.483014.

[21] C. Steinlicht and B. G. Garry, “Capstone project challenges: How industry sponsored projects offer new learning experiences,” in ASEE Annual Conference and Exposition, Conference Proceedings, 2014. doi: 10.18260/1-2–20144.