Abstract

Providing hands-on learning experiences increases student understanding of theory and practices in STEM (science, technology, engineering, and mathematics) fields. The experience gives students motivation and allows them to focus their career path towards completing a degree in a STEM field. This paper provides initial observations on the learning impact of community college students and their instructors participating in the Support Center for Microsystems Education 2021 Undergraduate Research Experience. Twenty undergraduate community college students and their instructors participated in a week-long hands-on project-based course in a cleanroom environment. Both students and instructors showed an increase in the level of knowledge regarding microfabricating based on the collected survey results after completing the program. Survey results and observations of participating mentors are presented.

Keywords: undergraduate education, microfabrication, cleanroom, MEMS, community college

© 2021 under the terms of the J. MNT Ed Open Access Publishing Agreement

Introduction

Hands-on approaches to learning are beneficial to students, maximizing students’ academic completion potential and better preparing them for success in the workforce. This can be especially true in STEM fields, where the development of “real-world” skills through practice is beneficial to not only the learners, but to future employers [1,2].

While theoretical (“book”) learning holds powerful value, the next generation of STEM practitioners needs to strive at putting theory into practice [3]. This is especially true while working in a technology-oriented career, where hands-on learning contributes to students’ enhanced interests in education continuation and core class attentiveness (i.e., engagement) [4]. Focusing on the microfabrication manufacturing field, previous undergraduate class curriculums have demonstrated success in student semiconductor manufacturing training and in making these students sought after by industrial employers [5]. The current semiconductor industry requires a wide variety of skilled workforce, from technicians to design engineers, with a high demand for skilled and trained workers in the relevant areas [6,7].

Finally, a hands-on education approach will also address the growing concerns of industry recruiters regarding a skill gap between the existing workforce and the incoming technician graduates [8]. Therefore increasing job-readiness is of high importance to the semiconductor industry, as it leads to decreased training time and costs. There is a wide range of application fields of typical micro-fabricated devices from the semiconductor industry, including communications, healthcare, computing, transportation, aerospace, among others [9]. Therefore, there is a need for highly skilled microfabrication technicians to fulfill these workforce demands [7]. Community college students can pursue technician jobs upon graduation or continue at the university towards an engineering career. Nonetheless, with a microsystems fabrication hands-on project-based experience added to their curriculum, both types of students benefit greatly, providing valuable and relevant cleanroom and microfabrication experience for the micro-nanotechnology (MNT) industry. This paper presents the initial observations of community college students’ and instructors’ learning impact in a microsystem fabrication-focused research experience based on their survey responses as presented below.

2. Methodology

A total of twenty participants, including at least five instructors, and twelve students from three community colleges, participated in the Microsystem fabrication-focused Undergraduate Research Experience (URE). The course consisted of the participants receiving online preparatory materials and lectures in the microfabrication area weeks before arriving at the laboratory, followed by a week-long hands-on cleanroom experience at the University of New Mexico (UNM). Two graduate teaching assistants and two UNM faculty members educated and mentored the participants in using multiple fabrications and metrology tools and processes. This classroom experience allowed students to work inside a class 1000 cleanroom at the UNM Manufacturing Training and Technology Center (MTTC), as seen in Fig. 1.

During the week, students participated in several microfabrication projects and received training on various cleanroom equipment, followed by completing the survey to analyze the experience’s impact. There were three main types of microdevices fabricated, namely i) a micro pressure sensor ii) microneedles and iii) microfluidic channels. An initial “Art Wafer” project was undertaken to introduce students to basic cleanroom processing and safety protocols. The Art Wafer Project included a photolithography step and wet chemical etch resulting in a pattern of the students’ choosing onto a 4-inch silicon dioxide coated silicon wafer. This initial project introduced the students to wafer cleaning procedures (i.e., solvent resist stripping and spin rinse dry (SRD) methods). They also gained training on the spin coater, mask aligner/exposure instrument, chemical fume hoods (including solvent and caustic wet materials), and wafer handling.

1. Microfabrication Methods

Making of a Micro Pressure Sensor

The micropressure sensor process is a simple two mask process that consists of multiple steps that expose students and faculty to many of the processes used in micro nanofabrication: 1) photolithography with positive and negative resists, 2) dry anisotropic etching, 3) wet anisotropic silicon crystal etching, 4) sputter deposition, 5) thin-film measurement, 6) wafer dicing, 7) optical microscopy, 8) scanning electron microscopy, and 9) electrical probe characterization of the Wheatstone bridge circuit.

The purpose of the photolithography process is to transfer a pattern to the wafer. Spin coating is the first step and is a technique used to deposit uniform thin films upon a substrate dispensing liquid material followed by spinning of the substrate (wafer). The centrifugal forces induced by the spinning, spread out the material, leaving behind a uniform thin film [10]. This is a standard method to deposit photoresists in photolithography procedures. Photolithography is a process where a photoresist, a photosensitive polymer, is exposed to light via a photomask using a contact or projection illumination system. This light exposure makes certain parts of the photoresist soluble (positive resist) or insoluble (negative resist) to the subsequent development step. After developing the photoresist, selective areas are covered with photoresist, and other areas are not. The photoresist protects what is underneath in the subsequent etching step or allows the selective deposition of material to the open areas (metal in the case of the pressure sensor process). In other words, the step following photolithography allows for different microfabrication techniques such as etching (removal of material) or material sputter (deposition or material) to transfer the photomask pattern into different material layers [10,11].

By the end of the week of cleanroom activities, the students learned how to fabricate and characterize a fully functional micro-pressure sensor. This completed device consists of a chrome-gold (CrAu) bi-layer or a single layer nichrome (NiCr) alloy piezoresistive Wheatstone bridge circuit on top of a thin film silicon nitride membrane. To create the device, there are two patterning steps. The first step is to create the opening for the sensor chamber, and the second is to create the actual bridge circuit. Fig. 2 shows the pressure sensor device; note the chamber viewed from the backside of the wafer and the Wheatstone bridge as seen from the top.

To create the chamber, one must first transfer the pattern to the backside of the wafer via photolithography and subsequent reactive ion etching of the silicon nitride film. The first step is to coat both sides of the wafer with a thick positive photoresist: AZ 10XT. Next, the front side is coated to protect the one-micron thin silicon nitride film from being damaged while processing the backside. Next, a series of open areas are patterned in the photoresist allowing for the selective removal of the silicon nitride using reactive ion etching (RIE). The photoresist is then removed. The patterned silicon nitride is now a “hard mask” for the subsequent etching of the crystal silicon wafer substrate resulting in the pressure sensor chamber. The RIE process uses a carbon tetrafluoride and oxygen (CF4/O2) gas combination with a plasma to open SiN windows. Next, the photoresist is stripped with acetone followed by an alcohol and deionized water quick dump rinse (QDR) and spin rinse dry (SRD).

To create the frontside Wheatstone bridge pattern, the front side of the wafer is patterned using one of two lift-offs resist processes, either LOR5B and AZ1518 or NLOF2070, a positive and negative resist process, respectively. This photolithography process step results in open areas on the wafer, which defined the Wheatstone bridge circuit. Once the pattern is defined, metal for the circuit is deposited into open areas on the SiN and on top of the photoresist. After sputter deposition, the photoresist is stripped and the wafer cleaned, resulting in the metal on top of it also being lifted off, leaving only the Wheatstone bridge circuit on top of the silicon nitride, which will become the flexible membrane of the pressure sensor.

The last step of the fabrication process is to etch the chamber. The wafer is submerged in a heated potassium hydroxide (KOH) bath. KOH selectively etches the exposed silicon crystal wafer substrate. The SiN does not etch in KOH; hence, only the open areas of the backside chamber pattern are exposed, and the exposed silicon is removed until the etch reaches the frontside SiN layer. Upon completion of the KOH etching, the Wheatstone bridge circuit is on top of a released SiN membrane which can now flex along with the circuit.

The students and faculty also were exposed to wafer dicing, the separation of the individual devices from the wafer, scanning electron microscope (SEM) inspection, and electrical probe testing of the device under varying pressure difference conditions. The probe station also includes an interferometer whereby the participants can determine the degree of membrane deflection, determine the change in the circuit resistor length and compare theoretical with actual voltage output.

Micro Fluidic and Needle Fabrication

Additionally, students learned how to fabricate micro-needles, focusing on three types of fabrication: i) cavity-based needles for soft-lithography ii) protruding silicon microneedles, and iii) 3D pillar needles. The process flow for the different types of needles is shown in Fig. 3. SU8 is a negative photoresist used in the process. When the cavity-based microneedles were patterned, polydimethylsiloxane (PDMS) was used as a flexible cast for the soft lithography of the cavity needles in order to produce replicas of the protruding microneedles by pouring the PDMS on top of the wafer and allowing it to cure. Once cured, the PDMS can be peeled away, leaving a soft-lithography mold. These PDMS needles can be seen in Fig. 4.

Similarly, students learned how to make traditional micro-fluidic channels utilizing similar soft-lithography methods. Surface micromachining methods (i.e., additive manufacturing) were demonstrated for microfluidics channels using negative photoresist SU8 on a Si Wafer. A photolithography process was used to pattern different microfluidic geometries. PDMS was used again for the soft-lithography mold. In Fig. 5a, a student can be seen peeling the PDMS mold away from the patterned SU8 profiles on the Si wafer. The final mold is shown in Fig. 5c. In this case, the mold was dyed red for visual purposes. Lastly, students and faculty were exposed to different methods to characterize these microdevices and structures using an electrical probe mechanical and optical-based metrology methods.

2. Survey Methods

Out of 20 participants in the program, 17 participated in a survey to rate their experience in this program. The online survey was shared on the last day of the cleanroom research experience, which included questions using the Likert scale (1-5) and short answer options.

The survey items included questions such as the following:

- How satisfied were you with the experience?

- Did you have any prior experience with hands-on microfabrication inside a cleanroom?

- What was your level of knowledge regarding microfabrication before and after starting the program?

- What is your field of study background? (i.e., degree currently seeking, previous experience)

- Which part of the hands-on experience did you learn the most? Explain why and what parts helped you bring your understanding to a higher level.

- Do you feel that you were introduced to new scientific concepts? Please Explain

- Please describe your familiarity with the different processes before and after the accelerated course.

- How likely are you to participate in a similar experience like this in the future?

- How likely are you to recommend it to your peers?

Similarly, when answering the question regarding their current field of study, the participants had the option of selecting multiple fields. The respective backgrounds are summarized in Fig. 6.

3. Survey Results

Instructors and students were asked to rank their familiarity with a number of microfabrication processes on a Likert scale from 1-5 before and after the course, with 1 meaning “You were not at all familiar” and 5 meaning “You were very familiar .”Fig. 7a and Fig. 7b show the responses to this question from the instructors and students for different processes, respectively.

For both the instructors and the students, there was a positive increase in the level of familiarity with each aspect of microfabrication. As seen in Fig. 7a, in the case of the instructors, there was an increase in familiarity for all of the microfabrication processes listed. The largest positive difference (+1) with a standard deviation of 0.44, was in Soft Lithography, which involved creating a mold of the microfluidic and microneedle structures by pouring and curing PDMS on top of the wafer substrate and then peeling it off. The smallest increase was in the Exposure section, with an increase of only (+0.2) and a standard deviation of 0.44. Exposure is one of the basic steps in the photolithography process and is an essential part of transferring a pattern to the wafer using a photoresist.

In the case of the students, the levels of familiarity, as seen in Fig. 7b, had a positive increase in each microfabrication category as well. The category which showed the highest student self-assessed knowledge was the Lift-Off process with an increase of (+2.42) and a standard deviation of 0.96. This process involves patterning thin metal film deposited on top of developed photoresist profiles and subsequently removing the metal-on-photoresist surfaces with solvents baths producing the Wheatstone bridge circuit. The area with the smallest increase (+1.78) with a standard deviation of 0.67 was interestingly in the area of soft lithography, which was a new exercise for most students.

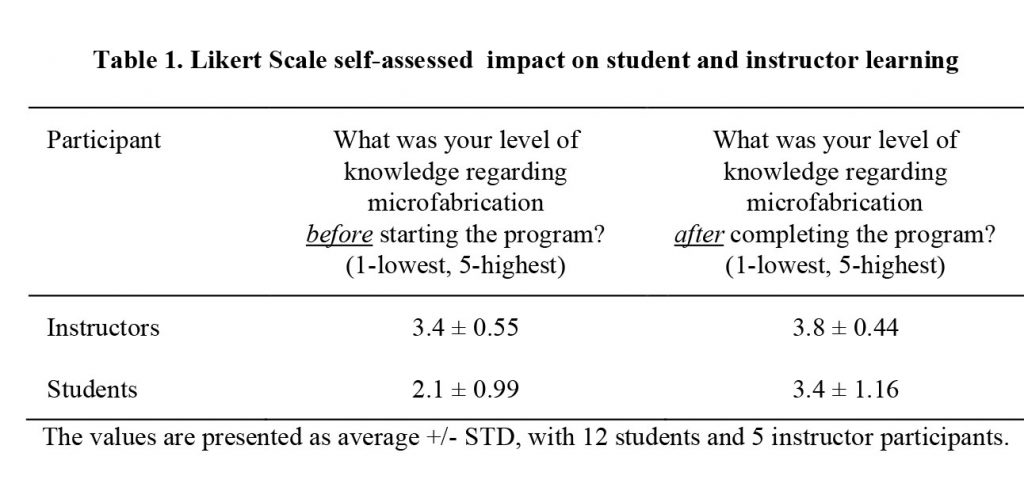

When asked a general statement regarding their knowledge before and after the class, the participants reported an increased level of knowledge corresponding to microfabrication processes. Table 1 summarizes this data, highlighting an overall improvement in a general understanding of microfabrication. After completing the program, the average instructor familiarity increased 11 %, and students increased by 61 % in terms of familiarity measured via a 1-5 Likert Scale.

When asked how likely the participants are to recommend it to their peers, 88.2% of the total participants selected “Highly Likely,” and the remaining 11.8% selected “Likely,” showing a positive assessment of the course. Responses to how likely the participants wou participate in a course like this in the future was similar, with 76.5% selecting “Highly Likely” and 23.5% selecting “Likely .”This is not a first-time event; however, it is the first time a survey has been presented to participants.

The following are direct quotes from instructor responses:

- “The equipment required (wet bench, fume hood, exposure tool, etc) is not only much more expensive that our Community College department budget could afford, but even could we find grant funding, our space limitations are considerable.”

- “Much of the SCME material is already very remote-friendly, however I think the hands-on cleanroom experience is invaluable.”

In their responses, the instructors noted how this was a valuable experience and beneficial to their learning. Instructors stated that from a pedagogy perspective, it might be difficult to create more lecture materials leveraging the recently covered topics; however, they intend to use the resources from this experience such as modified lecture slides, and adapt these into the delivery methods used in their courses.

4. Discussion

Given that this was a short online, week-long, hands-on research experience, the apparent trend of gained knowledge is vital. It increases microfabrication and cleanroom knowledge, skills, and familiarity for both students and instructors. These initial observations have shown that a hands-on microfabrication course is significantly beneficial for both instructors and students in STEM fields looking to gain practical cleanroom process experience, especially in the semiconductor/microfabrication fields. This has the potential to grow student employment in the semiconductor fields by giving them real-life experiences inside a cleanroom and exposure and familiarity with surface and bulk microfabrication techniques.

Hands-on learning has been shown to improve abstract concepts into a more concrete context and directly lead students to a higher chance of succeeding in STEM fields [12]. We can see this in the positive trend of results; considering this is primarily a one-week experience, the familiarity of the accelerated teaching is effective and beneficial.

Having students go through the entire process of fabricating a two-mask micro pressure sensor allowed them to see the complete process from the bare silicon wafer substrate through patterning, etching, and thin film deposition, and finally, device characterization. This permitted the participants to acquire the knowledge and skills needed to understand microfabrication and the ability to work in a clean-room setting.

When fabricating the microneedles, the students were exposed to creating similar structures through different methods, which contributes to understanding the process designs and how to modify these processes for different applications and geometries. For example, how to obtain longer microneedles or create a sharper needle tip from the different etching techniques applied.

Further, in fabricating a soft lithography mask for microfluidic applications, the students were able to apply MEMS fabrication techniques to create flexible final samples. These have a wide variety of bio-applications, such as wearable sensors or sensors for different types of bio-detection; this is of interest to many students. In addition, there is a wide range of applications of fabricated microdevices. For example, micro pressure sensors are used in technologies including biomedical applications, automotive industries, aerospace, among others [13,14]. Furthermore, microneedles can be used in areas such as transdermal drug delivery, biotherapeutics, and monitoring purposes [15,16]. Lastly, microfluidic channels have applications in the area of analytical processing of biological and chemical samples [17].

Students learning microfabrication through hands-on approaches have previously mentioned how hands-on teaching methods have engaged their interest [5,18,19]. Moreover, the area of MEMS (micro-electro-mechanical systems) is fundamentally centered on creating a device/system or can be thought of as product-oriented, so hands-on learning is appropriate. In the students’ case, this experience also introduced new fields of study, which helped students discover an interest in the semiconductor/microfabrication fields. As there is a vast number of STEM careers, it is essential to allow students to explore a variety of career paths, including process, equipment, quality control technical roles. Here are some comments from students:

- “As a student who knew nothing about MEMS before the UNM experience, this experience was extremely beneficial and gave me new insight into MEMS technology.”

- “I did not know anything about MEMS and their applications before participating in this experience. I learned more about possible careers that I could go into in the future.”

- “This experience not only expanded my scientific knowledge by introducing me to MEMS and the techniques needed to make MEMS but allowed me to better determine what I want my career path to look like.”

Similarly, some feedback provided by the instructors was received:

- “This is an unparalleled opportunity for whoever is new to nanotechnology.”

- “[Microfabrication is an] informative and useful research field that is prospering and growing which makes it beneficial for students to learn more about and potentially immerse oneself into this field.”

- “[I have ] already have suggested it to future students.”

Furthermore, we should note that most participants (64.7%) had never been inside a cleanroom before as most of them were community college students. In fact, 83.3 % of students had no prior experience with hands-on microfabrication inside a cleanroom; in the case of the instructors, this was only 20 %. The program introduced most students to the cleanroom for the first time, which was a valuable experience.

From the instructors’ feedback, it can be very costly to translate all hands-on teaching experiences to a community college that does not possess a cleanroom. Not only in terms of equipment and material costs but also in terms of laboratory space. This experience might be difficult to emulate in a non-cleanroom environment. This gained experience can be insightful for students who have never done hands-on microfabrication and have only studied microfabrication theories previously in their classes. Further, since most of these students are in an engineering technology program, this experience can pave the way for careers in the semiconductor industry.

5. Conclusions

he participants of a weeklong hands-on microfabrication course were comprised of instructors and students. Both surface and bulk micromachining methods were taught, with the participants completing a micro pressure sensor, different types of microneedles, and fabricating a soft lithography mold for microfluidic applications. Valuable and relevant knowledge was gained for both the instructors and students based on the feedback received at the end of the program. The students showed a significant increase in familiarity and understanding of the different fabrication methods: photolithography, isotropic and anisotropic wet etching, reactive ion etching, thin-film sputter deposition, cleanroom safety/protocol, photoresist development, measurement, and characterization methods, among others. This experience further introduced students to new possible career paths within the microsystems and semiconductor fields, both academic and industry options. Overall, initial observations of a community college hands-on microfabrication course proved beneficial and valuable for the participants.

Acknowledgments. We thank the members of UNM’s MTTC cleanroom staff for all their help. This material is based upon work supported by the National Science Foundation under DUE Grant No. 1700678.

Disclosures. The authors declare no conflicts of interest.

- J. S. Rolston and E. Cox, “Engineering for the Real World: Diversity, Innovation and Hands-on Learning,” Philos. Eng. Technol. 20, 261–278 (2015).

- R. Capraro, M. Capraro, and J. Morgan, STEM Project-Based Learning: An Integrated Science, Technology, Engineering, and Mathematics (STEM) Approach (2013).

- N. Katajavuori, S. Lindblom-Ylänne, J. H.-H. Education, and undefined 2006, “The significance of practical training in linking theoretical studies with practice,” Springer (n.d.).

- … R. B.-I. 56th I. M. S. on and undefined 2013, “Inspiring electrical engineering students through fully-engaged hands-on learning,” ieeexplore.ieee.org (n.d.).

- J. C.-C. E. Education and undefined 2002, “A hands-on laboratory in the fundamentals of semiconductor manufacturing: The capstone course of a new undergraduate option,” journals.flvc.org (2002).

- O. Bonnaud, A. B.-A. in technology, and undefined 2020, “Adaptation of the higher education in engineering to the advanced manufacturing technologies,” pdfs.semanticscholar.org 5, 65–75 (2020).

- S. Murph, A. Singh, K. C.- JOM, and undefined 2020, “Workforce Development Survey Results: Industry, Government Laboratories, Academia, and Recent Graduates,” researchgate.net (n.d.).

- M. Bell, “Sacramento valley advanced manufacturing & design workforce development pathways: A modern roadmap for industry careers based on community college skill,” (2017).

- M. Mishra, V. Dubey, … P. M.-… of E. R., and undefined 2019, “MEMS technology: a review,” mail.journaljerr.com 4, 1–24 (2019).

- R. Zaouk, B. Park, M. M.-M. Techniques, and undefined 2006, “Introduction to microfabrication techniques,” Springer (n.d.).

- S. Franssila, Introduction to Microfabrication (2010).

- J. C. Hayes and D. J. M. Kraemer, “Grounded understanding of abstract concepts: The case of STEM learning,” Cogn. Res. Princ. Implic. 2, (2017).

- C. Pramanik, … H. S.-… of M. and, and undefined 2006, “Design optimization of a high performance silicon MEMS piezoresistive pressure sensor for biomedical applications,” iopscience.iop.org (2006).

- K. B. Balavalad, S. Meti, K. B. Balavald, and B. G. Sheeparmatti, “MEMS piezoresistive pressure sensor: a survey,” researchgate.net 6, 23–31 (2016).

- S. Dharadhar, A. Majumdar, … S. D.-D. development and, and undefined 2019, “Microneedles for transdermal drug delivery: a systematic review,” Taylor Fr. 45, 188–201 (2018).

- Y. Kim, J. Park, M. P.-A. drug delivery reviews, and undefined 2012, “Microneedles for drug and vaccine delivery,” Elsevier (n.d.).

- S. Kim, S. Lee, K. S.-L. on a Chip, and undefined 2008, “Cell research with physically modified microfluidic channels: a review,” pubs.rsc.org (n.d.).

- R. Dahle, R. R.-I. T. on Education, and undefined 2016, “3-D printing as an effective educational tool for MEMS design and fabrication,” ieeexplore.ieee.org (n.d.).

- L. G. Fréchette, C. W. Wong, K. Chin, G. Georgiou, K. F. Farmer, F. Miller, and V. Modi, “Hands-On MEMS: Building Competence Through Practical Learning Experiences,” scholar.archive.org (2006).